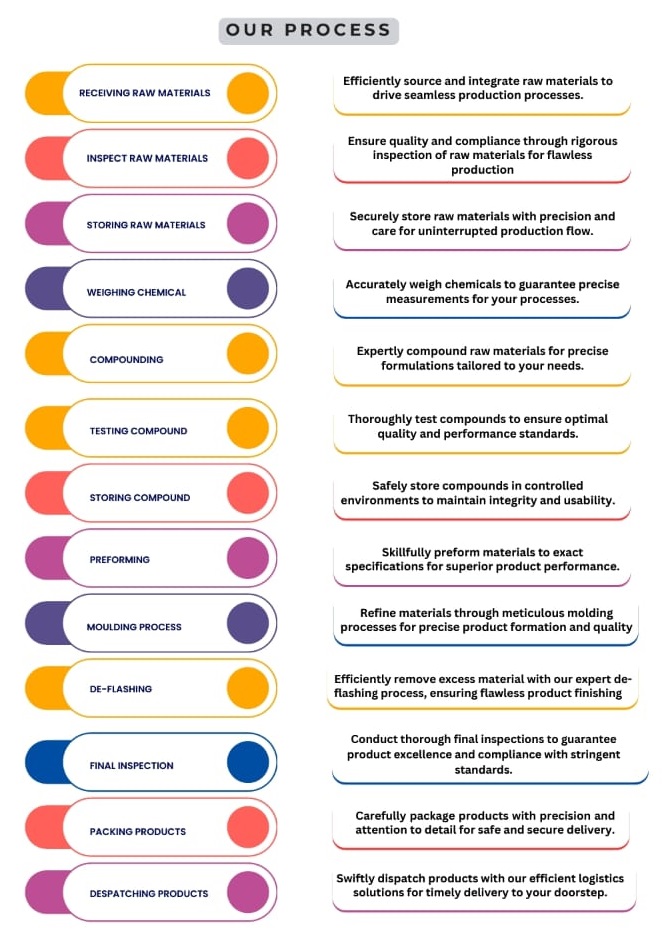

Our Process

“PSA Polycraft concentrate on quality and quantity. We have streamlined the process of work through years of experience and research.”

Our Process:

● Rubber Compounding

● Rubber Compression Moulding

● Plastic Injection Moulding

● Bakelite Compression Moulding

Rubber Compounding

Our Rubber compounding process is about blending and mixing various raw materials to create a customized rubber compound with specific properties. This intricate manufacturing process involves combining rubber polymers with additives, fillers, and chemicals to achieve desired characteristics such as flexibility, durability, resilience, and resistance to heat or chemicals.

PSA Polycraft elevates industries with precision rubber compounding, crafting tailored formulations that redefine performance standards. Our expertise ensures excellence in every compound, meeting diverse application needs with unmatched precision.

Rubber Moulding

PSA Polycraft’s Rubber Moulding manufacturing process involves shaping rubber material into desired forms using Moulds. The process typically includes heating the rubber to a pliable state, placing it into a Mould, and then allowing it to cool and solidify in the desired shape.

Rubber Moulding is widely used to produce a variety of products, ranging from simple gaskets and seals to more complex components used in diverse industries such as automotive, aerospace, and consumer goods. The method allows for the production of precise and intricate rubber parts with consistent quality.

PSA Polycraft offers cutting-edge rubber Moulding services, seamlessly shaping innovation and reliability into every product. Elevate your industry standards with our precision and expertise in customized rubber Moulding solutions.

Plastic Injection Moulding Process

Plastic injection Moulding is a manufacturing process that involves injecting molten plastic material into a Mould cavity. The process begins with the melting of plastic pellets, which are then injected under high pressure into a Mould. Once inside the Mould, the plastic material cools and solidifies, taking the shape of the Mould cavity.

This method is highly versatile and is widely used to produce a vast array of plastic components, ranging from intricate and small parts to larger and more complex items. Plastic injection Moulding is a cost-effective and efficient way to manufacture precise and consistent plastic components for various industries.

PSA Polycraft's plastic Moulding process combines advanced technology and precision engineering to create customized plastic components. Beginning with the selection of high-quality plastic materials, our process involves meticulous injection Moulding techniques. The molten plastic is injected into meticulously crafted Moulds under high pressure, ensuring uniformity and precision. The components then undergo a controlled cooling process, resulting in the final product. PSA Polycraft's plastic Moulding expertise guarantees the production of top-notch plastic components tailored to meet diverse industry requirements.

Bakelite Components Manufacturing Process

PSA Polycraft Bakelite components manufacturing process about to Moulding molten Bakelite material into desired shapes, followed by a curing process to solidify and form durable components, meeting specific industrial requirements with precision.

At PSA Polycraft, we start Bakelite components with selecting high-quality Bakelite material, which is then Moulded into specific shapes using techniques like injection or compression Moulding. The Moulded Bakelite undergoes a curing process to achieve hardness and stability. Cooling follows the curing step, and post-Moulding processes such as finishing and quality checks ensure the final components meet industry standards. PSA Polycraft's expertise ensures a streamlined and efficient Bakelite components making process tailored to diverse industrial needs.

PSA Polycraft's Bakelite components manufacturing process encompasses several key stages:

● Material Selection: Rigorous selection of high-quality Bakelite material to meet

specific requirements.

● Moulding Preparation: Precise preparation of Moulds tailored to the desired

Bakelite component specifications.

● Moulding: Injection of molten Bakelite material into the Moulds, allowing it to take

the required shape.

● Curing: Controlled curing process to solidify and strengthen the Bakelite

components.

● Finishing: Post-Moulding processes to refine the final appearance and properties of

the components.